Our Business

Battery Module & Pack

Technology

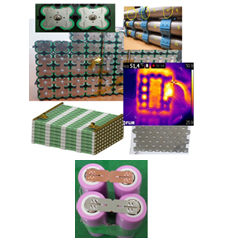

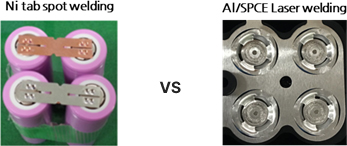

01Module Production Using Laser Welding Technology

Laser welding as an advanced module building technology

→ Manufacturing costs are reduced through excellent module balance, high reliability, and improved productivity.

| Spot welding | Wire bonding | Laser welding |

|---|---|---|

|

|

|

| Ni tab (Cond.15%) | Al10 (Cond.60%, 230W/mK) | Al10 (Cond.60%, 230W/mK) |

| Material Price : (10times) | 1/10 | 1/10 |

| Productivity : 1.5sec/cell | 1.5sec/cell | 0.1~0.3sec/cell (>4times faster) |

| 1S/4~32P large cell welding 6~12S/1~4P bolting connection |

Uni body type module | Uni body type module ★Optimal battery pack design for heat balance and a long cycle★ |

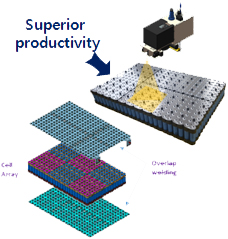

Strengths of Welded Modules

Al unibody module technology derived from laser welding boasts excellent electrical/thermal balance.

(Implementing a module with 'zero' contact resistance and optimized cell characteristics)

- One-body module of 1.0t Al Bus-plate

- Excellent voltage & thermal balance

- High electrical conductivity, heat generation

control, reliability against bration

- * Al Bus plate (230W/m.K)

- Heat from the battery cells spreads to the

Al tab and bus.

| 항목 | Ni (or Cu Alloy) | Al |

|---|---|---|

| Weight | 1 | 1 / 3 |

| Material Price | 1 | 1 / 10 |

| Conductivity | 15~18% | 60% |

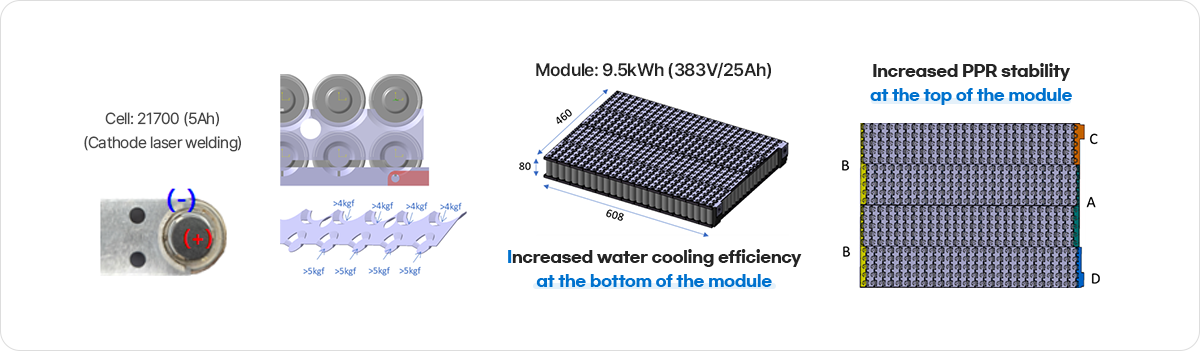

02Development of next-generation 4680/4690 battery cell modules

with a capacity 5 to 6 times that of 21700

03Leading Cy module technology by developing a laser welding module

for the top cathode of the 21700 cell

04Module Configuration Diagram

VE design, fusible Al bus, and FPC sensor applied

Reference

Cumulative performance of cylindrical battery modules and

packs in the EV/EM field - Approximately 120MWh (including ESS)

Total installed capacity of ESS battery: 50Mwh